The Physics of Glassware: Why Shape and Joints Matter in Chemistry

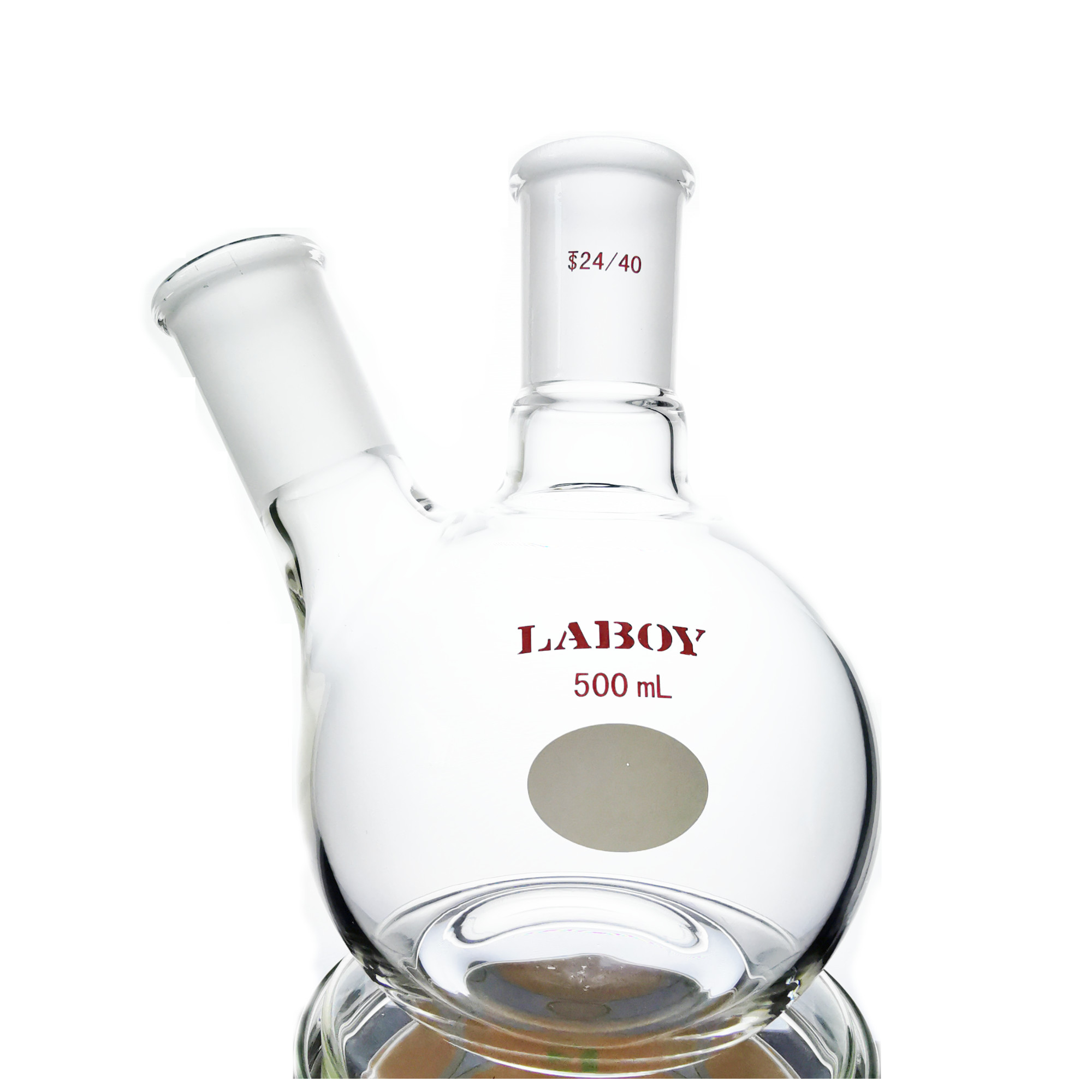

It’s not just about aesthetics—it’s about survival under pressure. We dive into the physics behind flask shapes, the “2-neck vs. 3-neck” debate, and why the geometry of your glassware is your first line of defense in vacuum safety.